Main Content

Resource Details

Flare stacks are used in many industries to burn off unwanted waste gas byproducts, or flammable gasses released by pressure relief valves during unplanned over-pressuring of plant equipment.

Figure 1: Thermal Monitoring of Flare

Applications include oil and gas well drilling operations, oil refineries, chemical process plants, gas distribution infrastructure, and landfills. In many cases, federal or state EPA regulations require the monitoring of a stack’s flame or the pilot flame that ignites the gases, to avoid having unburned hydrocarbons enter the atmosphere.

Risks

- Harmful unburned pollutants escaping into the atmosphere (CH4)

- Toxic air pollutants

- An explosion of unburned pollutants

- Hazard to the general public

- Fines and restrictions

Flare systems are often a last line of defence that prevents dangerous hydrocarbon pollutants from entering the atmosphere. One example is methane, which is not only combustible but is also 23 times more potent than CO2 as a greenhouse gas. A plant manager needs to know immediately if flare stack combustion is lost, and get the flame reignited quickly to prevent a plant shutdown.

Flare Monitoring

Various technologies have been tried for monitoring the pilot flame that ignites gas flow and detects the stack flame, with varying degrees of success. Many of these technologies are useless or poor at monitoring smoke from stake combustion, an important indicator of burn efficiency.

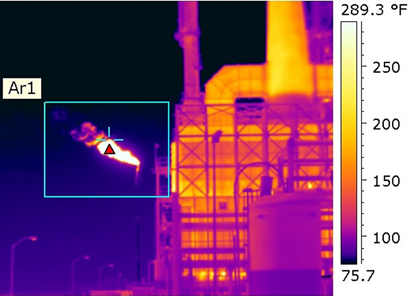

FLIR IR cameras recognize the difference in the heat signature of a flare stack flame and the surrounding background (usually, the sky or clouds). In addition to detecting stack flame, these cameras can be positioned to monitor the igniter flame.

Figure 2: Thermal cameras allow monitoring of Flares invisible to the naked eye

The images obtained with FLIR IR cameras allow an observer to detect stack flame that might not be visible to the naked eye because of its composition or low gas flow volume. This overcomes problems associated with UV flame detectors, which can be blinded by smoke. However, since the EPA considers excessive smoke an indication of poor combustion, IR cameras may be integrated with visual video cameras to monitor smoke. Thermographic and visual images can be transmitted in real-time to a central control room as either analog or digitized data.

In addition to visual monitoring of stack flame and smoke, automatic control of the assist gas to waste gas ratio is possible. When this ratio is properly adjusted, it improves combustion and minimizes smoke. Upset conditions require immediate adjustment of the air or steam volume to maintain proper combustion. As a bonus, automated assist gas injection control can help avoid excessive steam consumption, and provide significant cost savings.

POLLUTION CONTROL REQUIREMENTS

Environmental performance of gas-burning appliances is regulated at a state level. All states have slightly different regulations, but all have a similar regulatory structure. An activity that has a potentially significant environmental impact, is regulated by the state government usually through the EPA. Companies that undertake these activities are required to have an environmental license.

In landfills, the primary purpose of flare stacks is to burn the methane that results from the decomposition of organic material. In some countries operating under the Kyoto Treaty, garbage collecting companies are receiving a carbon bonus for installing flare stacks to burn the methane produced at their landfills. In Australia, the EPA typically bans the expelling of unburned methane into the atmosphere. They want to know that gas going up a flare stack is efficiently burned. Mandated controls include pilot flame monitors and stack flame detectors. Ideally, they want systems that automatically reignite the flame in case it goes out.