Main Content

Outcome Details

Ladle Inspection

OVERVIEW

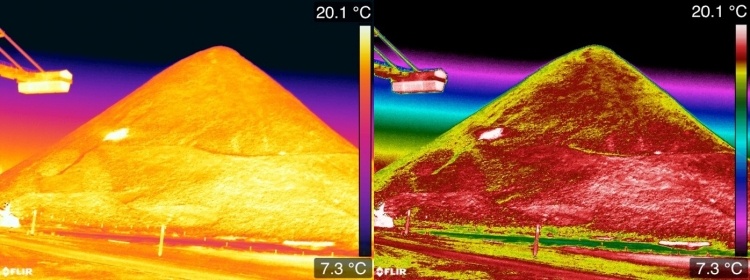

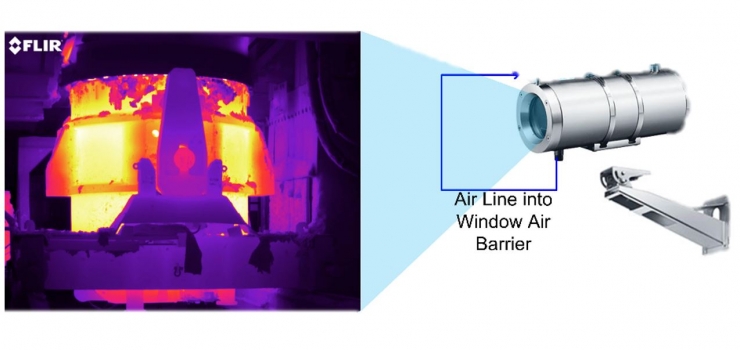

Most processes in the metallurgy industry require the use of casting ladles. These ladles are filled with molten steel, introducing a high degree of risk for a moving mechanism, which is compounded by the structural wear experienced by the ladle over its lifetime, due to the corrosive effects of molten steel.

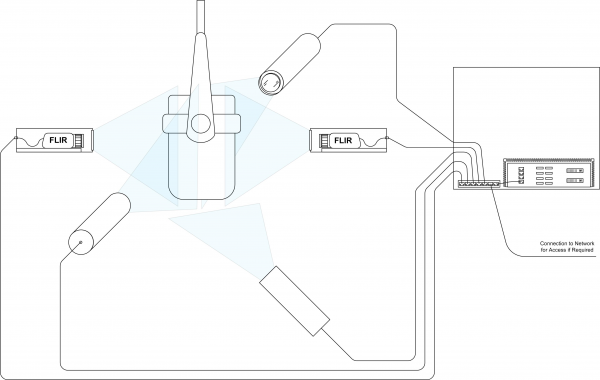

IMC has developed a thermal imaging solution to minimise this safety risk, utilising Ladle-Check software to enable automated inspection of ladles. This software has several key operations:

- Video analysis software automatically recognises when a ladle enters the inspection zone. A time stamp is recorded to the system log and thermal images of the ladle are stored to the server. The saved images include full radiometric data enabling later analysis of images.

- The software automatically identifies the ladle and records the minimum, maximum and average temperatures to the system log.

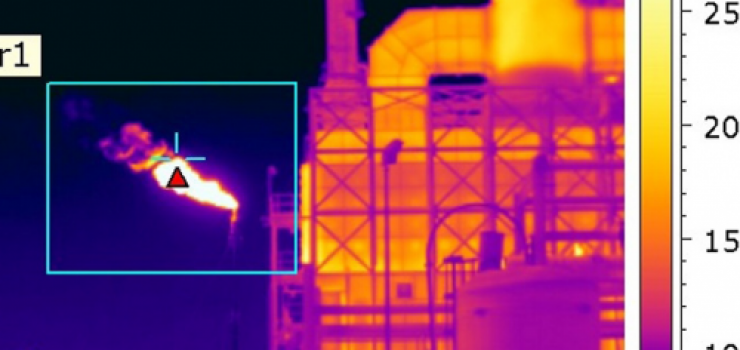

- If the system identifies a “hot spot” on the ladle an alarm is raised. This alarm is in the form of discrete I/O (dry contact). The sophisticated alarm algorithm is tuned for site-specific requirements and offers absolute threshold based alarms and relative peak based alarming.

- The system features a rolling-buffer of recorded thermal video footage, including full radiometric data. When a ladle is flagged as having a problem the footage is transferred to the server to allow detailed inspection of the ladle using advanced analysis functions.

HP Outcomes

Related Outcomes