Main Content

Outcome Details

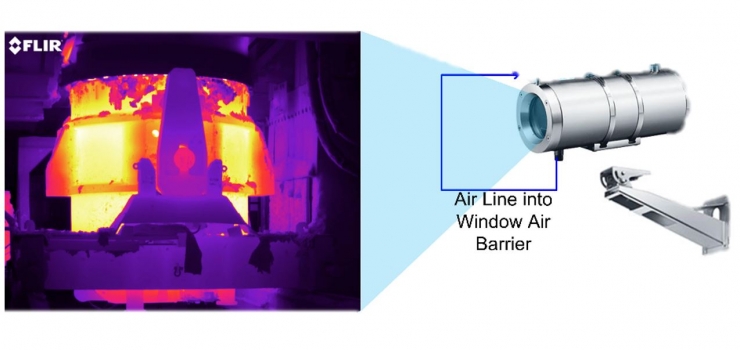

The storage of some material at waste sites, warehouses, fuel piles, and similar locations invites the risk of spontaneous combustion, either because of rising pressure or from unseen reactions within the stored materials. Thermal cameras hold the potential to detect abnormal heat sources before a fire can start. This is important when every second matters, and a fast response can help to stop a critical incident. Thermal anomaly detection is a common application, but there are a few important things to note:

- Thermal cameras are not primary fire detection devices. They are a complementary, supportive technology that can potentially provide early warning for thermal anomalies. They cannot be used for dialling the fire brigade, triggering deluge systems etc. Typically they are used to alert on-site supervisors via site radio systems or off-site 24/7 security monitoring services during non-operational hours, who can contact emergency services if required.

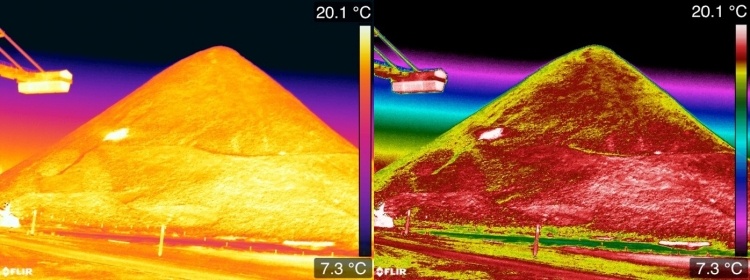

- Thermal cameras are a line of sight technology and will only see the surface heat of objects being monitored. This may mean that cameras on each side of the pile are needed for a stockpile. Similarly, suppose there is a heat source buried within a stockpile. In that case, this will not be visible unless there is an elevated temperature at the surface, for example, heat venting to the top of the pile.

- Pixel resolution matters. A temperature for every image pixel can be measured. Still, small hot objects will read cooler than the true temperature because the heat will be averaged with the cooler background temperature. This means that for large areas often, multiple cameras are required, or a narrow-angle of view lens camera on a pan-tilt base to scan a large area automatically.

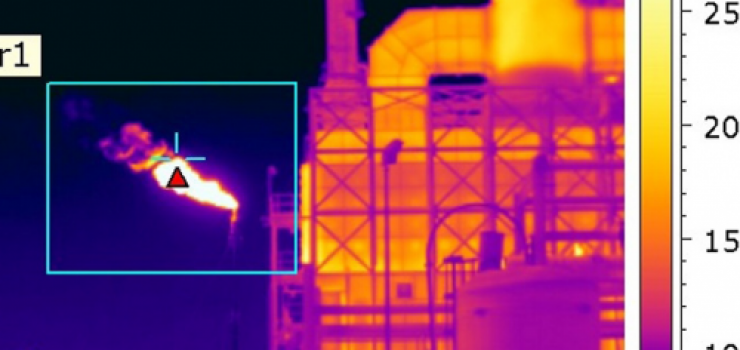

- Simple alarms, such as an over-temperature alarm, are susceptible to triggering heat sources like vehicle exhausts, sun reflections, etc. Consideration must be given to these factors during system design.

Front-end loaders and other machinery have exhaust stacks that can run at several hundred degrees. These cause most thermal camera systems to false alarm. The system developed by IMC in collaboration with the industry reduces these false alarms through advanced machine vision processing techniques. The system looks for things that "look like a fire", for example, a hot spot that is increasing in temperature or size over time. As such, the system can be effectively interfaced with video management systems, or send alerts via SMS and email.

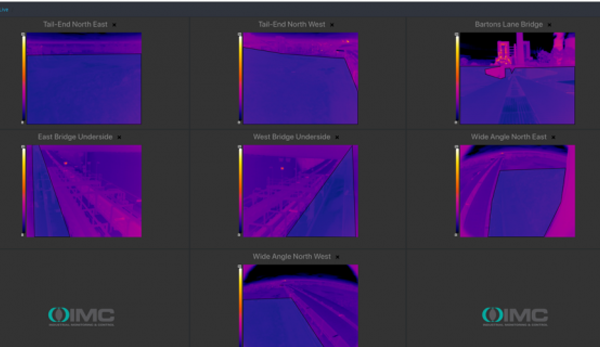

The system is scalable, from remote single camera systems operating as IoT devices through to enterprise grade >100 camera systems with fully virtualised processing servers.

Web-Based User Interface

IMC offers a configurable web-based user interface with many convenient features, allowing operators to interact with the fire warning system through any computer connected to the site network. These features include the ability to view live camera streams and alarms, reset or block alarms when necessary, select areas of concern in the camera FoV and view site maps with camera locations.

Extensions

Additional complimentary systems: