Main Content

Resource Details

Spontaneous combustion is a common occurrence when storing coal for extended periods of time. This may also be problematic when stockpiling waste/spoil materials that contain large quantities of coal. Early detection and prevention of spontaneous combustion is critical in order to prevent serious incidents occurring.

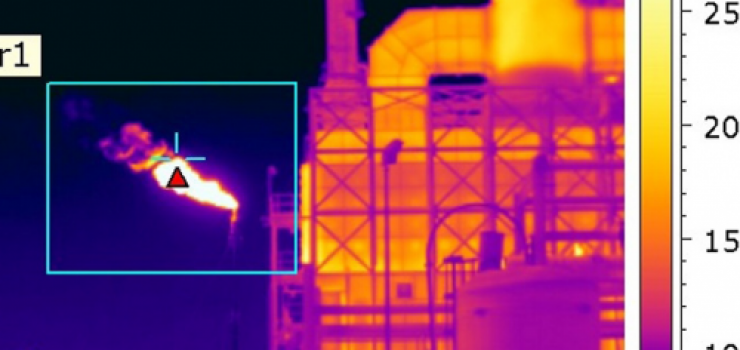

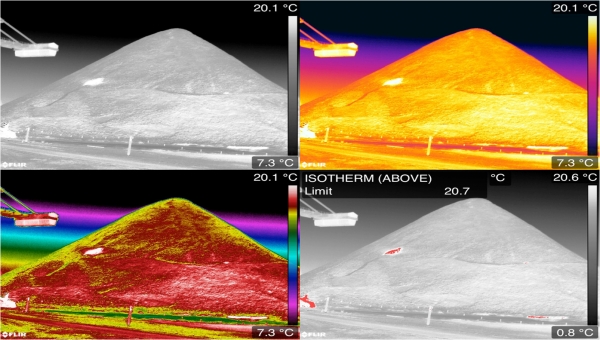

Figure 1. Early Detection of a hot spot on a stockpile that can lead to spontaneous combustion

How Does Spontaneous Combustion Occur?

Coal naturally oxidises over time. This causes an exothermic reaction that produces heat. The reaction is accelerated by the addition of further heat (sunlight, hot winds,etc). If the heat from the coal oxidising is trapped it will continue to self-heat and will eventually rise above the ignition temperature. Once the ignition temperature is reached the risk of spontaneous combustion is extremely high. At this moment only oxygen is needed to cause the coal to ignite and spontaneously combust. Since coal is a fuel source and is able to generate its own heat, the risk of a small fire quickly getting out of control is quite high.

Spontaneous combustion can happen with any soil with high coal content. This includes waste/spoil which may cause scrub fires if not disposed of properly.

Once a stockpile has spontaneous combusted it is hard to contain and extinguish. Typically the burning coal must be spread thinly over a wide area and be allowed to cool and extinguished with sprinklers. Applying sprinklers to the surface of a coal stockpile that has spontaneously combusted is typically not an effective method. If the coal is not spread out and extinguished, the coal will continue to self-heat enlarging the problem.

Risks Associated With Spontaneous Combustion

Besides the obvious risk of being a fire hazard and being hard to extinguish once established, the following risks are realised:

- Harmful green house gases are emitted (S02, NOx, H2S, CO)

- Fine particles will be emitted as a result of the combustion

- Harmful/Toxic air pollutants

- Odours that can travel via wind

- Hazard to the general public, waste/spoil piles can cause scrub fires

- Long-term problems such as soil contamination, rehabilitation in the case of spoil/waste piles

- Fines and restrictions

Spontaneous Combustion Prevention

To prevent spontaneous combustion one of the following factors must be removed:

- Fuel (The coal itself)

- Heat (Which can be either generated by the coal and/or solar radiation from the sun)

- Oxygen (Which is supplied readily through contact with air)

The fuel itself cannot be removed in coal stock piles. In waste/spoils the ratio of coal and be diluted to a level where the fuels are evenly spread over a large area.

Heat will always be generated if a large quantity of coal is lumped together. The problem is accelerated if the heat is allowed to be trapped and cannot escape. Typically moving the stock pile to another location every 2-3days can prevent the coal from accumulating enough heat to spontaneously combust. This method allows it to cool as it is travels on conveyors. Sprinklers can assist in curbing dust and lowering the risk of spontaneous combustion.

Oxygen can be removed by covering the coal with a sufficient quantity of top soil. This is only really applicable if the pile is waste/spoil.

None of these methods ensure that spontaneous combustion will not occur, they merely minimise the risk of the event occurring.