Main Content

Resource Details

Thermal imaging camera technology is now a widely accepted tool for the early detection of hot spots that pose a potential fire hazard.

Thermal imaging camera technology is now a widely accepted tool for the early detection of hot spots that pose a potential fire hazard. Permanently installed cameras operating parallel with conventional detectors offer a perfect complimentary technology with several key benefits over traditional technologies. Some benefits include:

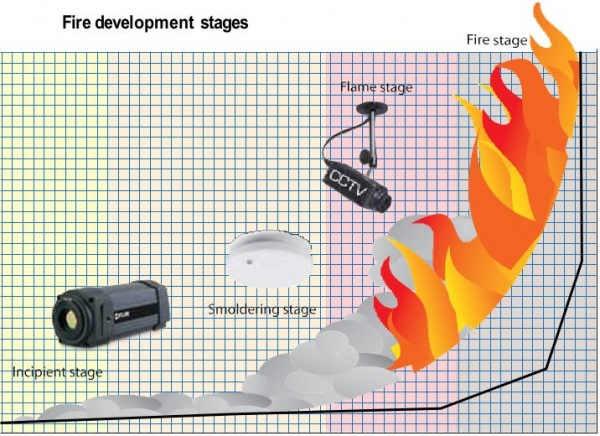

- As the cameras can “see” heat build-up, thermal imaging provides the ability to detect potential fire threats earlier – potentially before a fire can even start. This enables actions to be taken sooner, which can prevent the fire from occurring or, at a minimum, lessen its impact, improving safety and reducing costs to the business.

- Thermal imaging cameras can be less susceptible to issues with airborne dust and particulates, which can cause false alarms from traditional smoke detectors and cause visual smoke detection camera systems to fail.

Thermal imaging cameras are now manufactured by many companies and released under numerous brands. However, the imaging detectors used within these cameras, known as microbolometers, are only manufactured by a handful of firms globally. To ensure that a thermal anomaly warning system can operate effectively, it is important to understand some of the basic properties of thermal imaging detectors. These properties are common across all makes, models and brands that utilise common microbolometer sensors.

This article does not expect the reader to become a thermal imaging expert. Still, it aims to provide a broad overview of the technology and, more importantly, presents several questions that should be asked of any vendor offering thermal imaging technology for fire detection.

1.1 ARE THE CAMERAS “RADIOMETRIC”?

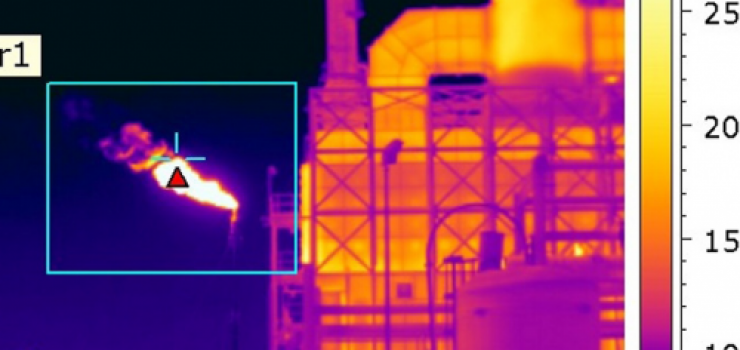

It is important to ensure that any camera proposed offers Temperature Measurement or Radiometry. Thermal Imaging Cameras capture thermal radiation in the long wave infrared region of the electromagnetic spectrum, far beyond what our eyes can see. A false colour palette is applied, giving each pixel of the image a colour based on the level of radiation reaching the detector – this provides the brightly coloured thermal images that we are accustomed to seeing in the media.

A radiometric thermal imaging camera goes one step further. For every pixel within an image, the camera calculates a temperature for the object being viewed. This is critical for thermal anomaly detection applications, as it enables temperature anomalies to be identified based on temperature thresholds, differentials or rates of change – allowing quantitative rather than qualitative analysis.

1.2 WHAT IS THE ACCURACY OF THE TEMPERATURE MEASUREMENT?

It is also important to understand the accuracy of the radiometric measurement. Typically, radiometric cameras will specify accuracy as “The greater of; ±5°C or ±5% of measured temperature”. In this example, temperatures <100°C will be in the ±5°C range. For temperatures >100°C, it will be in the ±5% range. Some cameras offer better accuracy, i.e. ±1%, ±2% etc., while others offer far worse accuracy, ±10% or more.

Hot spot detection applications do not require extremely accurate thermal imaging cameras. For example, the difference between 100°C and 102°C is of little consequence in most fire detection systems. However, cameras with an accuracy of ±5% or better are recommended, as accuracy worse than this can make setting alarming thresholds difficult.

For example, the ignition temperature for paper is approximately 230°C. If we want to set an alarm threshold to trigger at 220°C and our camera offers ±10% accuracy (±22°C), then we would need to set our alarm at 198°C to make sure we are alarming below 220°C. Having an alarm threshold set this much lower may dramatically increase false alarm rates caused by “acceptable” hot objects, such as vehicle exhausts (see alarm configuration section below).

1.3 DO ALL CAMERAS HAVE A LINE OF SIGHT?

It is a common misconception that thermal cameras can see into or through objects. Just like normal optical cameras, thermal imaging cameras only see the surface of the object they are viewing. This means that line of sight is required between the camera and any area that requires monitoring.

Fun fact: thermal imaging cameras cannot see through glass or Perspex as the longwave infrared radiation cannot pass through these materials. Thermal imaging cameras must be installed in specialised housings with windows usually made of Germanium.

Dynamic waste management sites have lots of moving vehicles and infrastructure. Camera mounting locations must not be impeded by equipment, or the camera will be ineffective. Roof mounting cameras to provide a top-down view can be a very good option in certain circumstances, as this reduces the risk of a camera's view being impeded by vehicle or machinery movements. It is important to ensure that all cameras have an unimpeded line of sight to any area that needs monitoring.

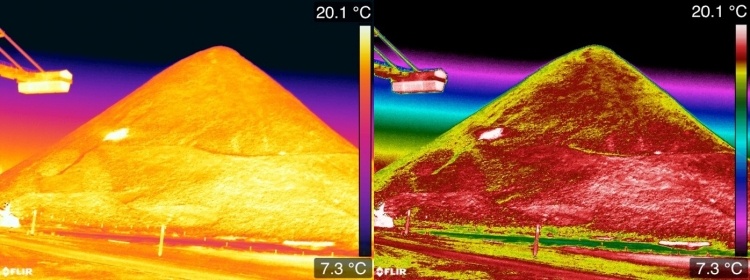

Side note: sometimes the cameras can detect heat below the surface. However, this is due to thermal differentials at the surface level. For example, the spots on the wall in the images below are because of glue behind the plasterboard that conducts thermal energy, resulting in cooler spots on the plasterboard surface. Similarly, the cameras can often see heat build-up below the surface in stockpile monitoring applications. This is because heat builds within the stockpile and is conducted through the material to the surface layer. Similarly, hot air venting from gaps within the material to the atmosphere can often cause heat to be detected at the surface. This allows the cameras to effectively detect heat build-up within some piles but is highly dependent on the type of material etc.

1.4 WHAT IS THE SPECIFIED CAMERA RESOLUTION AND LENS ANGLE? IS THE IFOV SUFFICIENT?

Radiometric thermal cameras can calculate the temperature for every pixel within an image. However, most cameras will require 3x3 pixels on a “spot” to measure that temperature accurately. Some cameras will require an even larger spot size, with some popular models requiring 10x10 pixels on target to get an accurate reading. This can dramatically limit the maximum working distance for a camera.

The size of a pixel of the camera is known as the instantaneous field of view (iFoV). If a hot object is smaller than this minimum size, then the temperature reading will be lower than the object's true temperature, as the reading will be averaged with the image background.

The below images show the tip of a soldering iron at 0.5 m, 1 m and 3 m distances. This effect significantly reduces the temperature reading at the furthest distance.

This effect is extremely relevant in thermal anomaly and potential fire hazard warning applications. If the installer attempts to use a camera with a lens angle that is too wide or a resolution that is too low, then the temperatures measured could be much lower than the actual temperatures. This can make warning systems ineffective, as the system may not detect hot spots or even small fires.

Each application will have different requirements for a minimum measurement spot size. For example, does the system need to detect heat accumulation in a large biomass stockpile that will present as a warm area of several square meters (say 1.5m x 1.5m)? Or is it looking for a small hot ember being ejected from a shredder into a mixed waste pile (say 6cm x 6cm)? These two examples would require vastly different iFoV to accurately calculate temperature (iFoV of 50cm vs 2cm).

Using wide-angle-of-view lenses is an effective way to get broad coverage and reduce overall system costs. There is a significant trade-off when taking this approach, and the installer needs to be certain that the iFoV at the target distance is small enough to accurately detect fire risks. This is where camera resolution comes into play. If we have two cameras with a horizontal angle of view of 45°. One camera has a resolution of 336 x 252 pixels. The other has a resolution of 640x512 pixels. For a given working distance, the measurement spot size for the 640x512 resolution camera will be a quarter the area of the 320x252 resolution camera. Conversely, for the required spot size, this will nearly double the maximum working distance and quadruple the maximum covered area for a 640 camera over a 320 camera.

1.5 WHAT IS THE ALARM CONFIGURATION?

Every site has different requirements and operating conditions, and there is no one size fits all approach to alarm configuration. The goal is to make the alarms generated by the thermal camera as sensitive as possible while minimising false alarms. Some basic alarm types are outlined below.

Over temperature alarms

The most basic form of alarm is an over-temperature alarm. For example, if a temperature within the image exceeds 150°C, raise the alarm. These alarms are very effective but also prone to false alarms. For example, loaders and other mobile machinery often have exhaust pipes venting at more than 250°C. Time delays can be placed on these alarms to reduce false alarms due to vehicle movements but can significantly reduce the alarm efficacy.

Temperature differential alarms

These alarms trigger when the difference in temperature between two points exceeds a defined threshold. For example, points could be located on multiple conveyor rollers. If one is significantly hotter than others, an alarm can be raised. In a stockpiling situation, this can also be used effectively by setting the alarm to trigger if any spot within the stockpile is greater than the average stockpile temperature by a predefined threshold. As above, differential alarms are similarly susceptible to false triggers on exhausts and other hot items.

Rate of change alarms

These alarms are based on a rate of temperature rise. For example, this may be useful for monitoring a static stockpile for temperature build-up that is a precursor to combustion. On dynamic sites with lots of vehicle movements, this type of alarm can reduce false detections while still offering an extremely effective way to monitor for ignition, typically identifying a fire significantly earlier than a traditional detector would identify a problem.

Multiple Profiles

Alarming configurations should be flexible. Any alarming system should offer multiple tiers of alert threshold and a hierarchy of actions based on the potential risk level. Systems should also allow conditional operating modes, for example, different thresholds based on different site operating states, i.e. load in, load out, unmanned, hot work etc.

1.6 WHAT SKILLS OR CERTIFICATIONS SHOULD I BE LOOKING FOR IN A SITE ASSESSOR?

The assessment of radiometric thermal imaging is called “thermography”. The science behind the technology is complex, and any integrator should have a comprehensive understanding of the fundamentals of thermography, i.e. emissivity, atmospheric transmission etc. Many sites have periodic thermal imaging inspections on mechanical plant and electrical switchboards. People offering this sort of inspection work should be qualified and certified by a professional body such as the Australian Institute for Non-Destructive Testing (AINDT) and/or the Australian Professional Thermography Association (AUSPTA). There are currently no requirements for individuals assessing sites for thermography-based fire detection. However, selecting an assessor with professional thermography experience is recommended.