Woodchip Stock Pile Spontaneous Combustion Early Detection

Spontaneous combustion is a common occurrence when storing woodchip for extended periods of time. Typically after a few weeks of storage with a high moisture content, the risk of spontaneous combustion is significant and must be considered. Spontaneous combustion is also a consideration in Hay, Straw, Cotton, Sugar Cane waste piles and compost piles. Early detection and prevention of spontaneous combustion is critical in order to prevent a serious incident occurring.

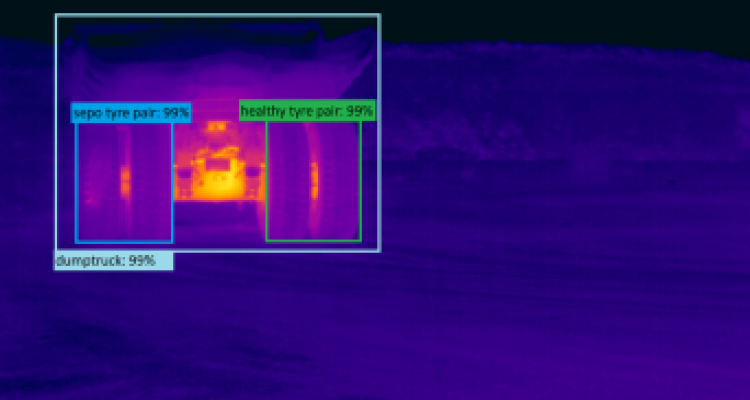

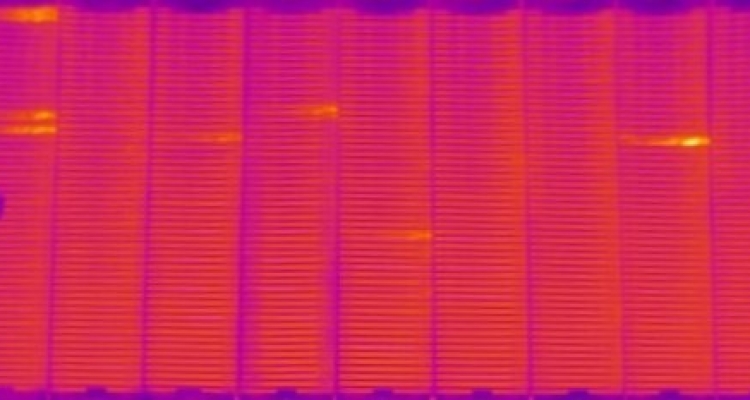

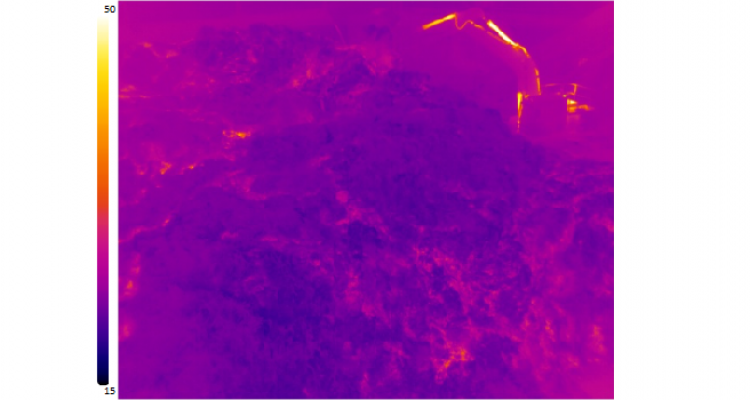

Figure 1. Early Detection of a hot spot on a stockpile that can lead to spontaneous combustion

Figure 1. Early Detection of a hot spot on a stockpile that can lead to spontaneous combustion

How Does Spontaneous Combustion Occur?

Bacteria naturally decomposes woodchip (and other organic materials) over time which in an exothermic reaction produces a significant amount of heat. The reaction is accelerated by the addition of further heat. Increased moisture content can accelerate heating compared to dry woodchip. If the heat from the decomposing woodchip is trapped it will continue to self-heat and will eventually rise above the ignition temperature. Since woodchip is a natural heat insulator, heat cannot escape and will continue to build the longer a pile is left to rest. Once the ignition temperature is reached the risk of spontaneous combustion is extremely high as only oxygen is needed to cause the woodchip to ignite and spontaneously combust. Since woodchip is a fuel source and is able to generate its own heat, the risk of a small fire quickly getting out of control is quite high.

Once spontaneous combustion has occurred it is hard to extinguish and manage.

Risks Associated With Spontaneous Combustion

Besides the obvious risk of fire and being hard to extinguish once established, the following risks are realised:

- Harmful green house gases are emitted (C02, CO due to incomplete combustion)

- Fine particles will be emitted as a result of combustion

- Harmful air pollutants

- Odours and Embers that can travel via wind

- Embers can be a hazard to the general public

- Fines and restrictions

Spontaneous Combustion Prevention

To prevent spontaneous combustion one of the following factors must be removed:

- Fuel (The woodchip itself)

- Heat (Which can be either generated by the woodchip and/or solar radiation from the sun)

- Oxygen (Which is supplied readily through contact with air)

The fuel itself cannot be removed in woodchip stock piles.

Heat will always be generated if a large quantity of woodchip is lumped together. The problem is accelerated if the heat is allowed to be trapped and cannot escape. Typically moving the stock pile to another location every week can prevent the woodchip from accumulating enough heat to spontaneously combust. Sprinklers can assist in curbing dust but may increase the risk of spontaneous combustion if the water content is allowed to get too high.

Oxygen can be removed by covering the woodchip with a sufficient quantity of top soil. This is only really applicable if the pile is waste/spoil.

None of these methods ensure that spontaneous combustion will not occur, they merely minimize the risk of the event occurring.

Spontaneous Combustion Early Detection

Early detection is critical in preventing spontaneous combustion. The first stage of spontaneous combustion is accumulating enough heat to ignite. The use of a radiometric thermal camera allows early detection of problem areas before they spontaneously combust. A radiometric thermal camera takes the guess work out of fire detection and prevention. It provides a means of detecting hotspots in stockpiles before they become problematic and cause downtime.

IMC have developed a deployable vehicle based thermal inspection system. By performing daily site inspections from a vehicle, potential problem areas can be identified days before spontaneous combustion has occurred.

Figure 2. IMCs deployable vehicle mount thermal inspection system

Using a non-contact FLIR long-wave infrared camera, the heat emitted from decomposing woodchip and be easily detected without the need for temperature measurement probes or complex site models.

The problem areas become easy to identify during hours when the sun has set as the reflected heat from solar radiation is removed and the woodchip starts to cool as the ambient temperature drops. Early morning is typically an excellent time to perform an inspection as the stockpile will be cool except for areas that have developing problems.

IMCs system can be easily detached from the vehicle and deployed out in the field temporarily. The video feed can be viewed remotely from offices as needed.

Figure 3. Detachable remote thermal monitoring system

Figure 3. Detachable remote thermal monitoring system

Designed for ease of use this system incorporates an wireless controller with inboard vehicle display. These features give this system extra flexibility and an ergonomic user interface.

Figure 4. Vehicle based thermal inspection system fully controllable from inside a vehicle

Location of hotspots can be geo-tagged an viewed on Google maps. This allows for a containment teams to effectively plan coordinate stockpile hazard mitigation. Having this system onsite enables early detection and prevention of stockpile spontaneous combustion. It provides a means of detecting hotspots in stockpiles before they become problematic and cause downtime.

Figure 5. Images taken with the system can be geo-tagged and viewed on google maps

The modular system can also be used for inspecting the entire plant as a whole. This can provide a means of efficiently carrying out noninvasive maintenance inspections for worn conveyors rollers, rubbing belts, heated bearings in large motors and much more.